The integrity system for processors

Processors play an important role in the integrity system. While livestock producers are responsible for keeping their integrity records in order and ensuring their on-farm practices align with integrity system requirements, processors must ensure that livestock consigned for processing are fit for consumption.

The Australian red meat integrity system combines livestock traceability with on-farm assurance to maintain the integrity and reputation of Australian red meat. This system underpins our livestock selling system and delivers customer confidence in the red meat products we produce.

Integrity Systems Company (ISC) is responsible for managing and delivering the core elements which make up Australia’s red meat integrity system.

Livestock Production Assurance (LPA)

Australian processors require producers to be LPA-accredited to be able to purchase their livestock.

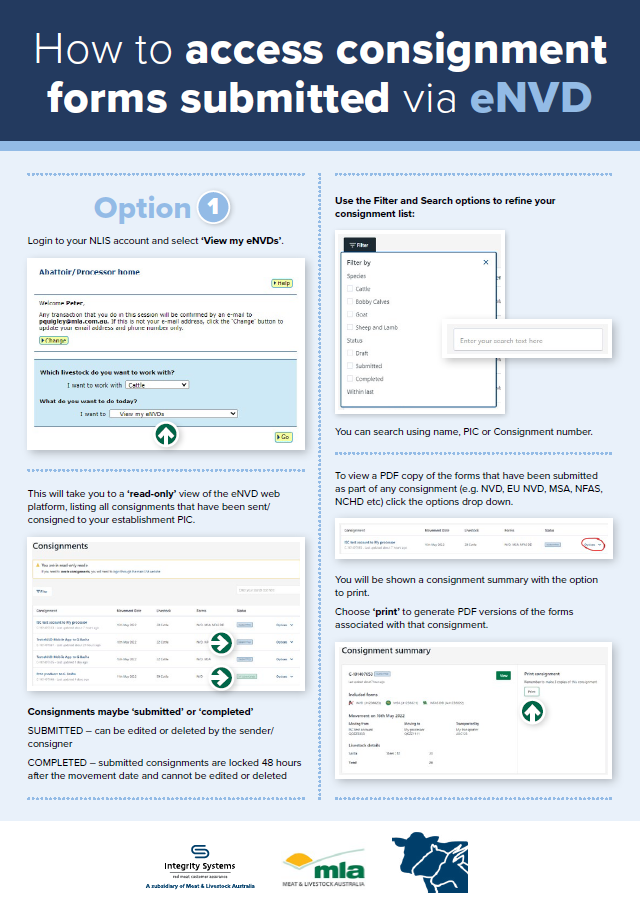

The current LPA National Vendor Declaration (LPA NVD) is required for all livestock movements, including property to property, through saleyards, direct to processors and to feedlots, and to the live export trade.

Processors must record information on the database to comply with state regulations relating to biosecurity and traceability.